Rubber manufacturing is a complex process that demands precision, durability, and efficiency. Whether producing tires, seals, gaskets, or custom rubber components, the quality of molds, dies, and machinery directly impacts the final product. Procuring these critical tools requires careful planning, technical expertise, and a strategic approach to ensure cost-effectiveness and operational success. In this blog post, we’ll explore the key considerations for procuring molds, dies, and machinery for rubber manufacturing, offering practical insights for manufacturers looking to optimize their production processes.

Before diving into the procurement process, it’s essential to understand the roles these components play in rubber manufacturing:

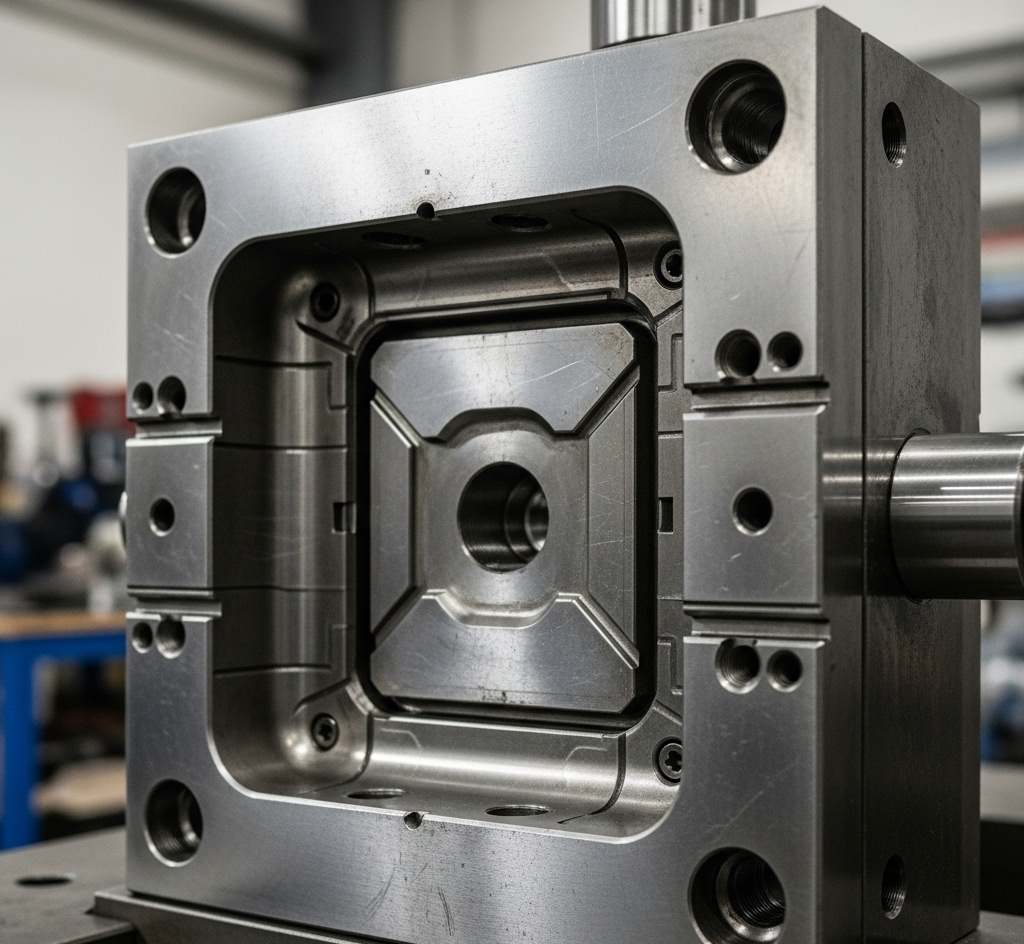

Molds: Molds shape the rubber into precise forms during processes like injection molding, compression molding, or transfer molding. They must withstand high temperatures, pressures, and repeated use while maintaining dimensional accuracy.

Dies: Dies are used in extrusion processes to form continuous rubber profiles, such as hoses, seals, or tubing. They require precise engineering to ensure consistent cross-sections and surface finishes.

Machinery: This includes equipment like injection molding machines, extruders, presses, and curing systems. Machinery must be reliable, efficient, and compatible with the specific rubber compounds and production requirements.

Each component is a significant investment, and poor choices can lead to production delays, quality issues, or increased costs. Let’s break down the procurement process to ensure you make informed decisions.

Start by clearly defining your production needs. Consider the following:

Product Specifications: What are the dimensions, tolerances, and material properties of the rubber components? For example, high-precision parts like O-rings require molds with tighter tolerances than less critical components.

Production Volume: Are you producing small batches or high-volume runs? High-volume production may justify investing in automated machinery or multi-cavity molds to increase efficiency.

Rubber Compound: Different rubber materials (e.g., silicone, EPDM, nitrile) have unique processing requirements. Ensure molds, dies, and machinery are compatible with the compounds you use.

Process Type: Will you use compression molding, injection molding, or extrusion? Each process requires specific equipment and tooling designs.

Creating a detailed specification sheet will guide discussions with suppliers and ensure they understand your needs.

The durability and performance of molds and dies depend on their material and construction. Common materials include:

Steel: High-strength tool steels like P20 or H13 are ideal for molds and dies due to their durability and resistance to wear and heat. For high-volume production, hardened steel is preferred.

Aluminum: Lightweight and cost-effective, aluminum molds are suitable for prototyping or low-volume production but may wear faster than steel.

Specialty Alloys: For demanding applications, such as high-temperature silicone molding, consider alloys with enhanced heat resistance.

Work with your supplier to balance material costs with the expected lifespan of the mold or die. For example, a more expensive steel mold may be cost-effective in the long run for high-volume production.

Finding reputable suppliers is critical to procuring high-quality molds, dies, and machinery. Consider these factors:

Experience: Look for suppliers with expertise in rubber manufacturing. They should understand the nuances of molding and extrusion processes and offer tailored solutions.

Customization Capabilities: Many rubber products require custom molds and dies. Ensure the supplier can design and manufacture tooling to your exact specifications.

Quality Certifications: Suppliers should adhere to industry standards like ISO 9001 to guarantee consistent quality.

Lead Times: Confirm the supplier’s ability to deliver within your timeline, especially for custom tooling, which can take weeks or months to produce.

After-Sales Support: Reliable suppliers offer maintenance, repair, and technical support to keep your equipment running smoothly.

Request quotes from multiple suppliers and compare their offerings based on quality, cost, and delivery timelines. Visiting their facilities or reviewing case studies can also provide insights into their capabilities.

When procuring machinery, prioritize efficiency, reliability, and scalability. Key considerations include:

Automation: Automated machines, such as servo-driven injection molders, improve precision and reduce labor costs, especially for high-volume production.

Energy Efficiency: Modern machinery with energy-saving features can lower operational costs, particularly for energy-intensive processes like curing.

Scalability: Choose equipment that can accommodate future growth. For example, modular systems allow you to add capacity as production demands increase.

Maintenance Requirements: Opt for machinery with accessible parts and straightforward maintenance procedures to minimize downtime.

Test machinery in real-world conditions, if possible, to ensure it meets your performance expectations. Partnering with manufacturers who offer training and ongoing support can also ease the integration process.

Procuring molds, dies, and machinery is a significant investment, so careful budgeting is essential. Consider both upfront and long-term costs:

Upfront Costs: Include the cost of molds, dies, machinery, and installation. Custom tooling can be particularly expensive, so explore options like multi-cavity molds to maximize output per cycle.

Operating Costs: Factor in energy consumption, maintenance, and labor costs when selecting equipment.

Total Cost of Ownership (TCO): A cheaper mold or machine may have a shorter lifespan or higher maintenance costs, increasing TCO. Evaluate the long-term value of your investment.

Negotiate with suppliers to secure favorable terms, such as discounts for bulk orders or financing options for expensive machinery.

Ensure that molds, dies, and machinery comply with industry regulations and safety standards. For example:

Regulatory Compliance: Equipment used in industries like automotive or medical must meet standards like IATF 16949 or FDA requirements.

Safety Features: Machinery should include safety guards, emergency stops, and ergonomic designs to protect operators.

Environmental Considerations: Choose equipment that minimizes waste and emissions, aligning with sustainability goals.

Verify compliance through certifications and third-party audits to avoid costly penalties or production delays.

Before full-scale production, test molds, dies, and machinery to ensure they meet performance expectations. Conduct trial runs to:

Verify dimensional accuracy and surface finish of molded or extruded parts.

Assess cycle times and production efficiency.

Identify potential issues, such as mold sticking or uneven extrusion.

Collaborate with suppliers to make adjustments during the testing phase to avoid costly rework later.

Build Strong Supplier Relationships: Long-term partnerships with reliable suppliers can lead to better pricing, faster delivery, and priority support.

Plan for Spare Parts: Keep critical spare parts for machinery on hand to minimize downtime in case of breakdowns.

Invest in Training: Ensure your team is trained to operate and maintain new equipment effectively.

Monitor Performance: Track key performance indicators (KPIs) like cycle time, defect rate, and equipment uptime to optimize production and identify areas for improvement.

Procuring molds, dies, and machinery for rubber manufacturing is a strategic process that requires careful planning and attention to detail. By defining your requirements, selecting high-quality materials, partnering with reputable suppliers, and prioritizing efficiency and compliance, you can build a robust production system that delivers consistent, high-quality rubber products. Investing time and resources upfront will pay off in improved productivity, reduced costs, and enhanced product quality, positioning your manufacturing operation for long-term success.

© 2025 Lasso Supply Chain Software LLC

Get instant access to our report on the Top Procurement Trends of 2025 by filling out the form below.

Get instant access to our report on the Top Procurement Trends of 2025.