Manufacturers and designers deal with fluctuating material demands, specialized suppliers, tight timelines, and the constant need for precision.

Manufacturers and designers deal with fluctuating material demands, specialized suppliers, tight timelines, and the constant need for precision.

From submitting purchase requests to approving budgets and tracking orders, these platforms streamline operations and help organizations control spending.

Long-lead components, which can take weeks, months, or even over a year to procure (think specialized PC boards or custom metal parts), and high-cost equipment components, which tie up significant capital, present unique challenges.

With the advent of machine learning (ML) and artificial intelligence (AI), organizations are unlocking unprecedented efficiencies, cost savings, and innovation.

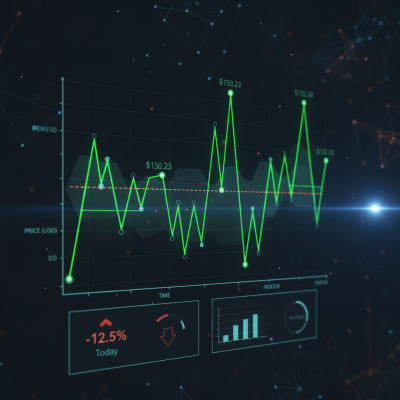

These settings are characterized by massive transaction volumes coupled with unpredictable demand fluctuations, supply chain disruptions, volatile prices, and external factors such as geopolitical tensions or regulatory changes.

From different gauges of cables and wires to switches, transformers, circuit breakers, and countless accessories, the sheer volume and variety of products pose significant challenges.

Sourcing software has revolutionized how companies procure goods and services, and at the heart of this transformation lies the supplier portal.

No longer confined to sci-fi novels or experimental pilots, AI is embedding itself into daily operations, reshaping how teams source, negotiate, and manage suppliers.

A Purchase Order (PO) process is essential for managing spending, ensuring compliance, and maintaining financial accountability as your company scales.

Whether your goals include cost reduction, innovation, sustainability, or risk mitigation, a well-aligned sourcing strategy can drive efficiency, foster strong supplier relationships, and contribute to long-term growth.

© 2025 Lasso Supply Chain Software LLC

Get instant access to our report on the Top Procurement Trends of 2025.