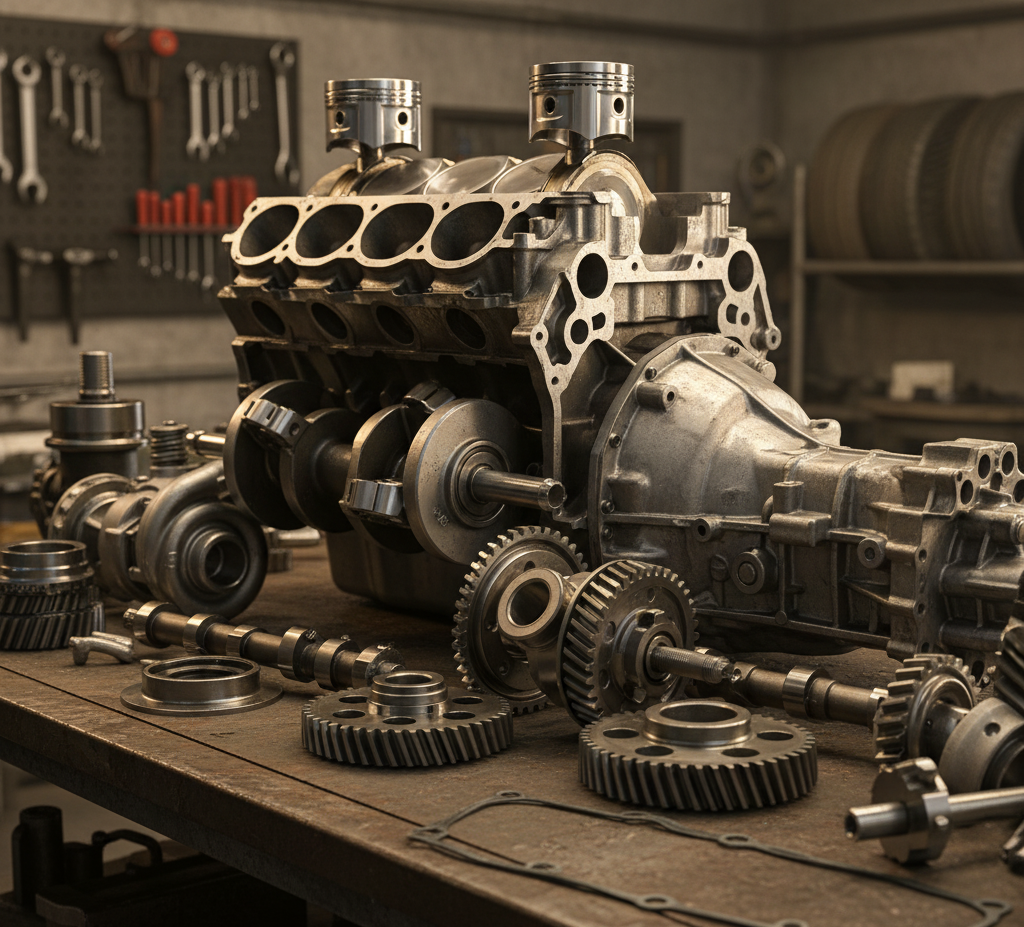

In the high-stakes world of aerospace and automotive manufacturing, where precision and reliability can mean the difference between seamless operations and catastrophic failures, supplier risk management (SRM) isn’t just a best practice—it’s a lifeline. Critical engine and gear components, such as turbine blades, pistons, transmissions, and differentials, form the backbone of these industries. A disruption in their supply chain doesn’t just delay projects; it can compromise safety, inflate costs, and erode customer trust. As global events like geopolitical tensions and natural disasters continue to test supply chains, organizations must adopt robust SRM strategies to safeguard their operations.

This blog post explores the unique challenges of managing risks for these vital parts, outlines proven mitigation tactics, and draws on real-world examples to illustrate how forward-thinking companies stay ahead of the curve.

What Makes Engine and Gear Components "Critical"?

Critical components are those whose failure could lead to mission-critical breakdowns, regulatory violations, or even loss of life. In aerospace, engine parts like compressor blades and combustion chambers endure extreme temperatures and stresses, demanding flawless metallurgy and assembly. Gear systems in automotive applications, including helical gears and planetary sets, must withstand high torque while maintaining silent, efficient performance.

These parts often involve complex, multi-tier supply chains: raw materials from one continent, machining on another, and final assembly elsewhere. Sub-tier suppliers—those further down the chain—handle specialized tasks like heat treatment or coating, yet their visibility is notoriously low. This opacity amplifies risks, as a single weak link can cascade into widespread issues.

The Top Risks in Supplier Chains for Critical Parts

Supply chains for engine and gear components face a multifaceted threat landscape. Here are the most pressing risks:

Geopolitical and External Disruptions: Conflicts, trade tariffs, and sanctions can halt imports of rare earth metals or alloys essential for gears and engines. The aerospace sector, for instance, is particularly vulnerable to such instability, with events like regional conflicts disrupting titanium supplies critical for engine casings.

Quality and Compliance Failures: Substandard materials or manufacturing defects can lead to part recalls. In safety-critical applications, non-compliance with standards like AS9100 (aerospace quality management) or IATF 16949 (automotive) isn’t just costly—it’s dangerous.

Sub-Tier Invisibility: Many OEMs overlook risks from second- or third-tier suppliers, where issues like labor shortages or environmental non-compliance brew undetected. This lack of visibility has plagued aerospace supply chains, leading to delays in component delivery.

Cyber and Financial Vulnerabilities: Suppliers handling proprietary designs are prime targets for cyberattacks, while financial instability can cause sudden bankruptcies, stranding orders for high-value gear sets.

Statistics underscore the urgency: Recent analyses show that supply chain disruptions have increased production costs by up to 20% in the automotive sector alone.

Strategies to Fortify Your SRM Framework

Effective SRM transforms potential pitfalls into managed variables. Drawing from industry frameworks, here are actionable steps tailored to critical components:

Conduct Rigorous Due Diligence and Segmentation: Before onboarding, evaluate suppliers on financial health, ethical practices, and technical capabilities. Segment suppliers by risk level—treat those providing single-source engine forgings as “high-risk” and prioritize them for deeper audits. For safety-critical equipment, this includes site visits and third-party certifications.

Diversify and Build Resilience: Avoid over-reliance on one supplier by implementing dual-sourcing for key gears or engines. Buffer stocks of critical spares and explore nearshoring to mitigate geopolitical risks.

Leverage Technology for Real-Time Monitoring: Digital tools like AI-driven risk platforms can scan for emerging threats, from weather events to supplier financial dips. In aerospace, digitizing supply chains enhances forecasting and sub-tier traceability, reducing blind spots.

Foster Collaborative Relationships: Engage suppliers in joint risk assessments and development programs. This “supplier development” approach improves quality while sharing the burden of compliance.

Integrate End-to-End Processes: Adopt a holistic SRM model with intelligent decision-making at its core—using data analytics to prioritize risks and simulate scenarios like a gear supplier strike.

By embedding these into your operations, you can achieve not just compliance, but competitive advantage.

Real-World Lessons: Case Studies in Action

Theory meets practice in these examples:

Automotive Supply Chain in Brazil: A study of the Brazilian automotive industry revealed how electronic integration risks in engine components led to widespread disruptions. By implementing SCRM practices like regular audits and contingency planning, manufacturers reduced downtime by 30% and stabilized gear production lines.

Aerospace Small Component Manufacturer: A tier-one supplier faced escalating risks from sub-tier partners during volatile market conditions. Through targeted risk tolerance modeling and diversified sourcing, the firm maintained delivery of critical engine housings, avoiding multimillion-dollar penalties.

These cases highlight a common thread: Proactive SRM doesn’t eliminate risks but equips teams to respond swiftly.

Charting a Resilient Future

Supplier risk management for critical engine and gear components is an evolving discipline, demanding vigilance in an interconnected world. By prioritizing due diligence, diversification, and digital innovation, companies in aerospace and automotive can turn vulnerabilities into strengths—ensuring their engines roar and gears turn without a hitch.

Get the White Paper: Streamlining Procurement Processes for SMB Manufacturers

Get instant access to our white paper on Must-Know Procurement Tips for SMB Manufacturers by filling out the form below.

Get in Touch

Learn more about Lasso supply chain solutions for SMB manufacturers

Please complete the form and we will be in touch as soon as possible.