In the fast-paced world of wood manufacturing, efficiency, cost control, and supply chain reliability are critical to staying competitive. Procurement software has emerged as a game-changer, streamlining operations and driving significant improvements across the industry. From raw material sourcing to inventory management, this technology is revolutionizing how wood manufacturers operate. Below, we explore the key ways procurement software transforms wood manufacturing operations.

Streamlined Supplier Management

Wood manufacturing relies heavily on a steady supply of raw materials like timber, adhesives, and finishes. Procurement software centralizes supplier data, enabling manufacturers to evaluate vendor performance, track pricing trends, and maintain strong relationships. With real-time insights into supplier reliability and lead times, companies can make informed decisions to avoid delays and ensure consistent material quality.

For example, a furniture manufacturer can use procurement software to compare lumber suppliers based on cost, delivery speed, and sustainability certifications, ensuring they source high-quality wood at the best price.

Optimized Inventory Control

Overstocking or understocking raw materials can disrupt production and inflate costs. Procurement software integrates with inventory systems to provide real-time visibility into stock levels, helping manufacturers maintain optimal inventory. Automated reorder points and demand forecasting tools ensure that materials like plywood or hardwood are available when needed without tying up capital in excess stock.

This level of control minimizes waste, reduces storage costs, and prevents production bottlenecks, which is especially critical in high-volume operations like cabinetry or flooring production.

Cost Reduction and Budget Control

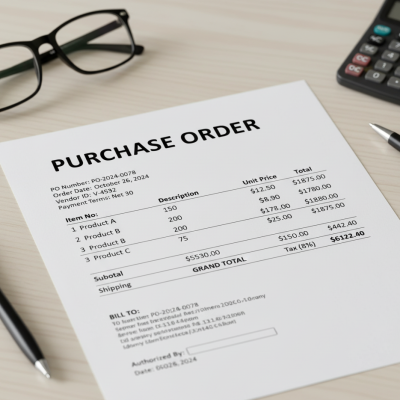

Procurement software enables wood manufacturers to analyze spending patterns and identify cost-saving opportunities. By consolidating purchasing data, the software highlights areas where bulk buying, negotiating better terms, or switching suppliers can reduce expenses. Additionally, it automates purchase order creation and approval workflows, reducing manual errors and unauthorized spending.

For instance, a millwork company can use the software to track spending on specialty woods and negotiate better rates with suppliers, directly impacting the bottom line.

Enhanced Supply Chain Transparency

The wood manufacturing industry often faces challenges related to supply chain disruptions, such as delays in timber deliveries or fluctuating material costs. Procurement software provides end-to-end visibility into the supply chain, from raw material sourcing to delivery at the factory. This transparency allows manufacturers to anticipate disruptions, track shipments, and adjust production schedules accordingly.

Moreover, many procurement platforms support sustainability tracking, helping companies verify that their wood sources comply with environmental regulations and certifications like FSC (Forest Stewardship Council).

Improved Compliance and Reporting

Regulatory compliance is a significant concern in wood manufacturing, particularly regarding environmental standards and labor practices. Procurement software simplifies compliance by maintaining detailed records of supplier certifications, purchase histories, and material origins. Automated reporting tools generate audit-ready reports, saving time and reducing the risk of non-compliance penalties.

For example, a wood panel manufacturer can use the software to ensure all sourced timber meets regional environmental regulations, streamlining audits and certifications.

Faster Decision-Making with Data Analytics

Modern procurement software comes equipped with advanced analytics that provide actionable insights. By analyzing historical purchasing data, market trends, and supplier performance, manufacturers can make data-driven decisions. For instance, predictive analytics can forecast price increases for lumber, prompting manufacturers to secure contracts before costs rise.

This data-driven approach empowers wood manufacturers to stay agile in a volatile market, ensuring they remain competitive even during supply chain challenges.

Integration with Manufacturing Systems

Procurement software often integrates seamlessly with other manufacturing systems, such as ERP (Enterprise Resource Planning) or MES (Manufacturing Execution Systems). This integration creates a unified workflow, where procurement data feeds directly into production planning and scheduling. For example, when a batch of lumber is ordered, the software can automatically update the production schedule, ensuring machines and labor are allocated efficiently.

Conclusion

Procurement software is transforming wood manufacturing by streamlining supplier management, optimizing inventory, reducing costs, and enhancing supply chain transparency. By leveraging data analytics and seamless integrations, manufacturers can make smarter decisions, ensure compliance, and boost operational efficiency. As the industry continues to evolve, adopting procurement software is no longer optional—it’s a strategic necessity for staying ahead in a competitive market.

Ready to transform your wood manufacturing operations? Explore procurement software solutions today and unlock the potential for smarter, more efficient production.

Get the White Paper: Streamlining Procurement Processes for SMB Manufacturers

Get instant access to our white paper on Must-Know Procurement Tips for SMB Manufacturers by filling out the form below.

Get in Touch

Learn more about Lasso supply chain solutions for SMB manufacturers

Please complete the form and we will be in touch as soon as possible.