In today’s rapidly evolving industrial landscape, smart and autonomous machinery is transforming sectors like manufacturing, agriculture, construction, and logistics. These advanced systems, powered by artificial intelligence (AI), Internet of Things (IoT), and robotics, are redefining efficiency, precision, and scalability. While engineering and R&D teams often take the spotlight for these innovations, the role of procurement is increasingly critical in driving this technological revolution. Procurement is no longer just about cost savings—it’s a strategic function that fuels innovation by connecting organizations with cutting-edge technologies, fostering supplier collaboration, and ensuring sustainable, scalable solutions.

Procurement has evolved from a transactional function to a strategic driver of business outcomes. In the context of smart and autonomous machinery, procurement teams are tasked with sourcing advanced components, software, and expertise that power these systems. By aligning with organizational goals, procurement professionals are enabling companies to stay ahead in a competitive market. Here’s how:

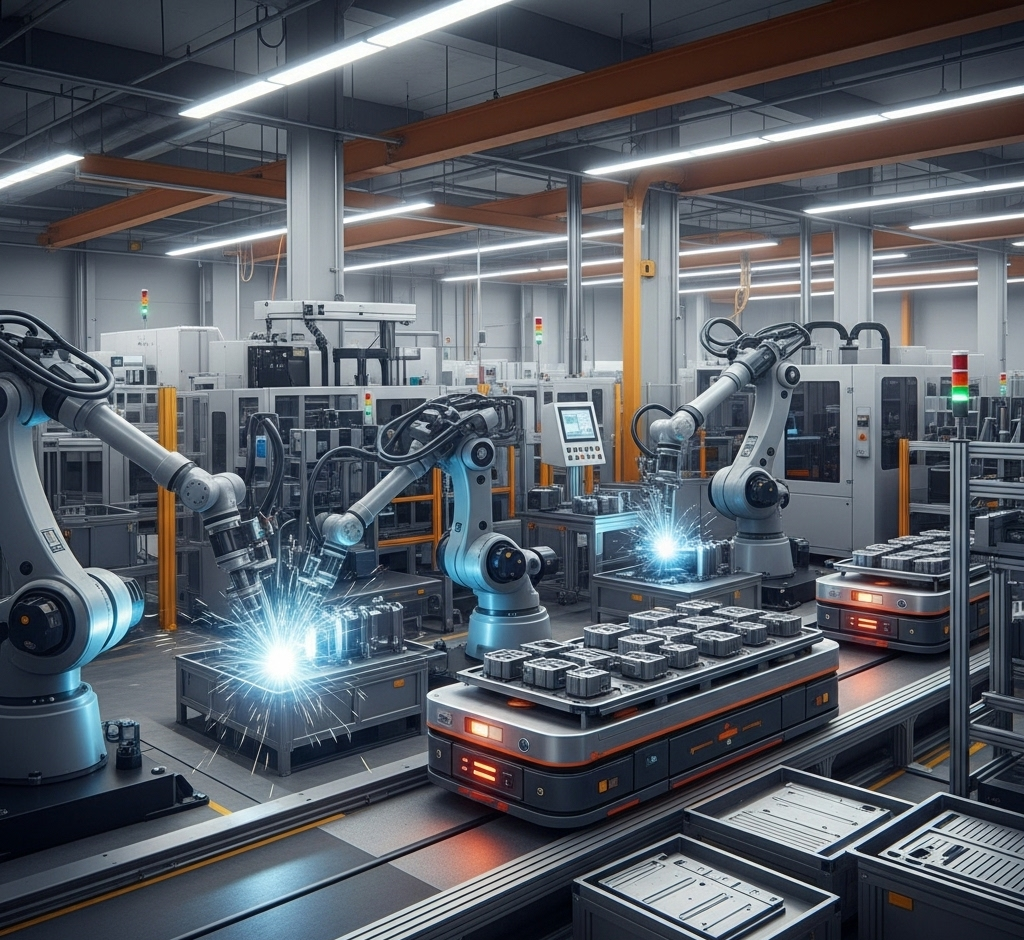

Smart and autonomous machinery relies on sophisticated components like sensors, AI algorithms, and advanced robotics. Procurement teams play a pivotal role in identifying and securing suppliers who can deliver these technologies. By staying informed about emerging trends—such as advancements in machine learning or 5G connectivity—procurement professionals ensure their organizations have access to the latest innovations. For example, sourcing high-precision LiDAR systems for autonomous vehicles or IoT-enabled sensors for predictive maintenance can give companies a competitive edge.

Innovation thrives on collaboration, and procurement acts as the bridge between organizations and their supplier ecosystems. By building strong relationships with suppliers, procurement teams can co-develop customized solutions tailored to specific needs. For instance, a procurement team working with a robotics supplier might collaborate to design a modular robotic arm that integrates seamlessly with existing production lines. These partnerships often lead to breakthroughs that drive efficiency and performance in smart machinery.

While innovation is critical, procurement teams must balance the pursuit of advanced technologies with cost considerations. By leveraging data analytics and market insights, they can negotiate contracts that secure high-quality components at competitive prices. This ensures that investments in smart and autonomous machinery deliver both innovation and financial value. For example, procurement can identify cost-effective AI software solutions that enhance machine autonomy without breaking the budget.

Sustainability is a growing priority in machinery development, and procurement is at the forefront of this shift. By prioritizing suppliers with eco-friendly practices—such as those producing energy-efficient components or using sustainable materials—procurement teams contribute to greener innovations. For instance, sourcing battery systems for autonomous machinery that use recyclable materials or have lower carbon footprints aligns innovation with environmental goals.

The impact of procurement on smart and autonomous machinery is evident across industries:

Manufacturing: Procurement teams source AI-powered vision systems that enable robots to perform complex tasks like quality inspection with unprecedented accuracy.

Agriculture: By securing IoT-enabled sensors and autonomous drones, procurement supports precision farming, optimizing crop yields and reducing resource waste.

Logistics: Procurement facilitates the adoption of autonomous delivery vehicles by sourcing advanced navigation systems and collaborating with software providers to ensure seamless integration.

Despite its critical role, procurement faces challenges in driving innovation. Rapid technological advancements require procurement teams to stay agile and informed about emerging trends. Additionally, global supply chain disruptions can complicate access to cutting-edge components. However, these challenges also present opportunities. By investing in digital tools like procurement software and predictive analytics, teams can streamline sourcing processes and anticipate supply chain risks, ensuring a steady flow of innovative solutions.

As smart and autonomous machinery continues to evolve, procurement will play an even more pivotal role. The rise of Industry 4.0, with its focus on interconnected systems and data-driven decision-making, will demand procurement teams that are tech-savvy, collaborative, and strategic. By embracing digital transformation and fostering innovation-driven supplier relationships, procurement will not only support but actively shape the future of smart machinery.

Procurement is no longer a behind-the-scenes function—it’s a catalyst for innovation in smart and autonomous machinery. By sourcing cutting-edge technologies, fostering supplier collaboration, balancing cost with innovation, and prioritizing sustainability, procurement teams are driving the next generation of industrial advancements. As industries continue to embrace automation and intelligence, procurement will remain a cornerstone of progress, ensuring that organizations stay at the forefront of technological innovation.

© 2025 Lasso Supply Chain Software LLC

Get instant access to our report on the Top Procurement Trends of 2025 by filling out the form below.

Get instant access to our report on the Top Procurement Trends of 2025.