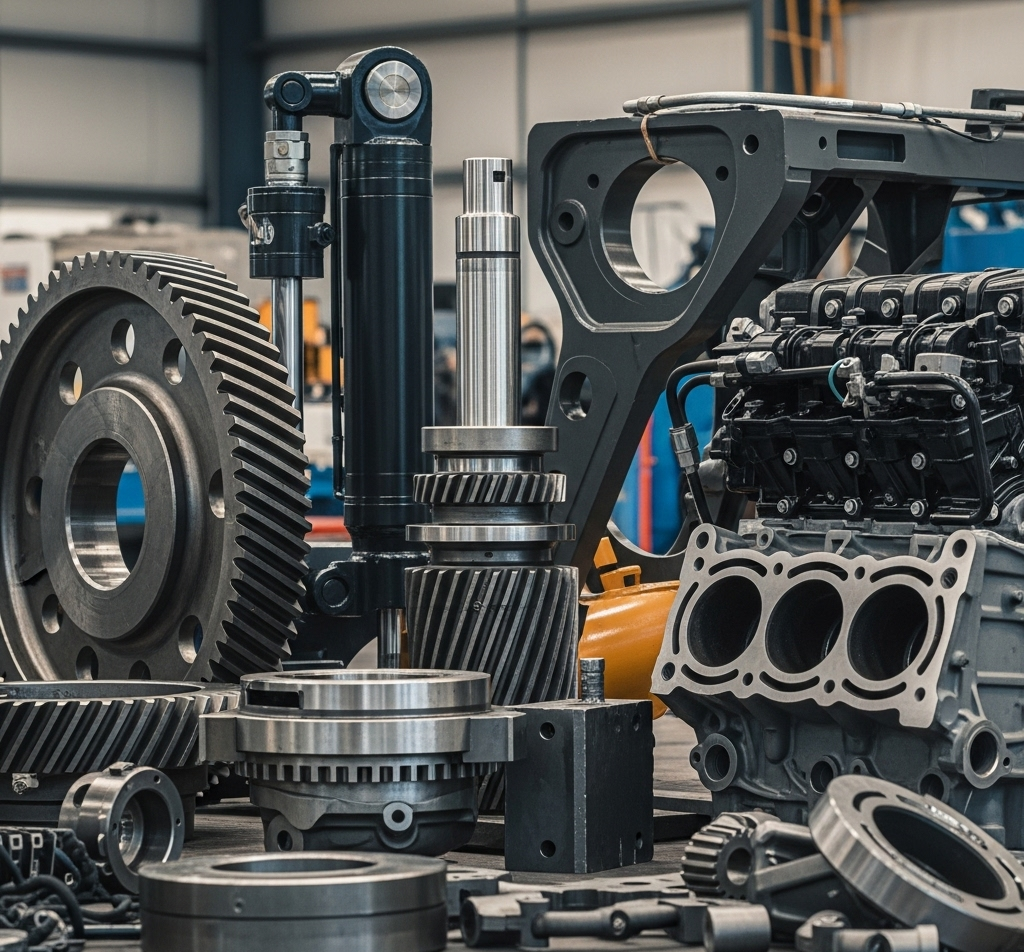

In the world of heavy equipment manufacturing and maintenance, reliability is everything. Whether you’re building excavators, bulldozers, or mining machinery, the custom machined and fabricated parts you source can make or break your operation. These components—think precision gears, structural frames, or hydraulic fittings—must withstand extreme conditions like high loads, abrasion, and environmental stressors. Sourcing them effectively isn’t just about finding the cheapest option; it’s about partnering with suppliers who deliver quality, timeliness, and innovation.

If you’ve ever dealt with downtime due to faulty parts or scrambled to meet production deadlines, you know the stakes. In this blog post, we’ll walk you through a step-by-step guide to sourcing custom machined and fabricated parts for heavy equipment. Drawing from industry best practices, we’ll cover everything from identifying your needs to ensuring long-term supplier relationships. Let’s dive in.

Before you even start looking for suppliers, get crystal clear on what you need. Vague specs lead to mismatched parts, wasted time, and costly revisions.

Pro Tip: Use tools like finite element analysis (FEA) software to simulate part performance before sourcing. This ensures your specs are realistic and optimized.

The supplier landscape is vast, but not all are equipped for heavy equipment demands. Focus on those with expertise in CNC machining, sheet metal fabrication, and large-scale assembly.

In recent years, there’s been a shift toward nearshoring due to supply chain disruptions, with many companies favoring U.S. or Mexican suppliers over overseas ones for faster turnaround.

Once you have a shortlist, dig deeper. Not every supplier who claims “custom capabilities” can handle the rigors of heavy equipment.

A thorough vetting process might include site visits or virtual audits to see their operations firsthand.

Now it’s time to get numbers. Send out RFQs (Requests for Quotes) to 3-5 suppliers for comparison.

Remember, the lowest bid isn’t always best; factor in total cost of ownership, including potential rework or failures.

Don’t commit to full production without validation.

Sourcing doesn’t end with delivery—it’s an ongoing process.

Sourcing custom machined and fabricated parts for heavy equipment is a blend of technical know-how, strategic planning, and relationship management. By following these steps, you’ll not only secure high-quality components but also enhance your operational efficiency and competitiveness. Start small, learn from each sourcing cycle, and scale confidently.

© 2025 Lasso Supply Chain Software LLC

Get instant access to our report on the Top Procurement Trends of 2025.

Get instant access to our report on the Top Procurement Trends of 2025 by filling out the form below.