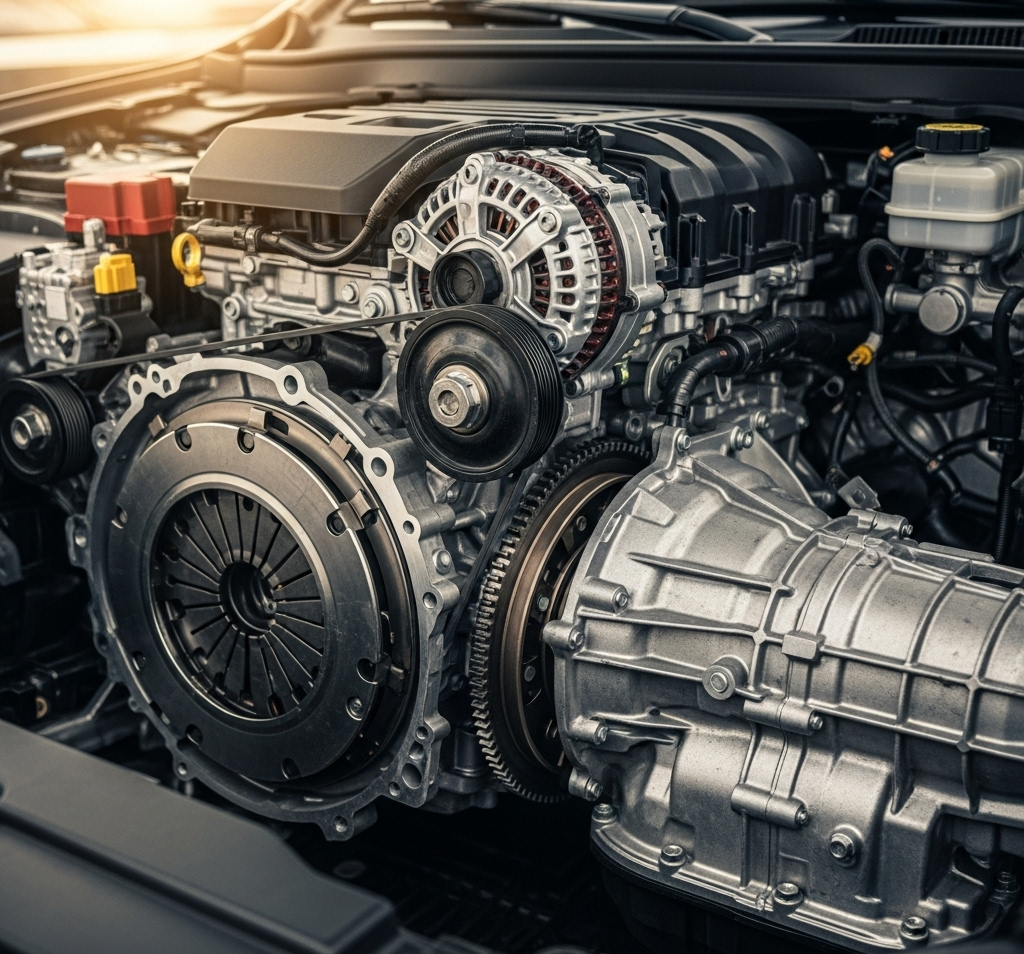

In industries like automotive, aerospace, and heavy machinery, high-spec engine and powertrain components are critical for performance and reliability. However, these precision-engineered parts often come with long lead times due to complex manufacturing processes, stringent quality requirements, and supply chain constraints. Effectively managing these lead times is essential to keep projects on schedule, control costs, and meet customer expectations. This blog post explores strategies to navigate these challenges and optimize the procurement of high-spec components.

High-spec engine and powertrain components, such as turbine blades, crankshafts, or electric vehicle battery systems, require advanced materials, intricate machining, and rigorous testing. Several factors contribute to extended lead times:

Complex Manufacturing Processes: Components often involve specialized techniques like precision forging, CNC machining, or additive manufacturing, which are time-intensive.

Material Sourcing: High-performance alloys, composites, or rare earth metals may have limited suppliers, leading to delays in raw material availability.

Quality and Compliance: Strict industry standards (e.g., ISO, AS9100) demand extensive testing and certification, adding weeks or months to production schedules.

Supply Chain Bottlenecks: Global disruptions, such as geopolitical issues or logistics delays, can impact the timely delivery of components.

Limited Supplier Capacity: Specialized manufacturers often have constrained production schedules, prioritizing existing contracts.

Understanding these root causes is the first step in developing strategies to mitigate delays.

To minimize the impact of long lead times, companies can adopt proactive approaches to planning, supplier management, and process optimization. Here are key strategies:

Engaging suppliers early in the design phase can significantly reduce lead times. By collaborating with manufacturers during product development, engineers can align designs with supplier capabilities, avoiding costly revisions. Early engagement also allows suppliers to reserve production capacity and provide accurate lead time estimates.

Actionable Tip: Schedule design reviews with key suppliers to ensure manufacturability and discuss potential bottlenecks.

Example: An automotive OEM working on a new hybrid powertrain could involve a battery supplier during the prototype phase to align on specifications and timelines.

Building long-term partnerships with reliable suppliers can secure priority access to production slots and materials. Trusted suppliers are more likely to provide transparency on lead times and work collaboratively to meet deadlines.

Actionable Tip: Develop framework agreements with suppliers to guarantee capacity and streamline procurement processes.

Example: A heavy machinery manufacturer might sign a multi-year contract with a forging supplier to ensure consistent supply of high-spec crankshafts.

Accurate demand forecasting helps align production schedules with component availability. By maintaining strategic inventory buffers for critical parts, companies can avoid disruptions caused by unexpected delays.

Actionable Tip: Use predictive analytics to model demand based on historical data, market trends, and project timelines.

Example: An aerospace company could stockpile critical turbine components based on forecasted maintenance schedules for its fleet.

Relying on a single supplier increases risk. Diversifying the supplier base across multiple regions or vendors can mitigate disruptions caused by capacity constraints or geopolitical issues.

Actionable Tip: Qualify secondary suppliers for critical components, even if they’re used as a backup.

Example: An electric vehicle manufacturer might source battery cells from multiple suppliers in Asia and Europe to reduce dependency on a single region.

Advanced technologies like digital twins, additive manufacturing, and supply chain visibility platforms can streamline processes and reduce lead times.

Digital Twins: Simulate manufacturing processes to identify bottlenecks before production begins.

Additive Manufacturing: Use 3D printing for rapid prototyping or low-volume production of complex parts.

Supply Chain Platforms: Implement real-time tracking tools to monitor supplier progress and logistics.

Actionable Tip: Invest in Industry 4.0 solutions to enhance visibility and collaboration across the supply chain.

Example: A powertrain manufacturer could use a digital twin to optimize the production process for a new transmission component, cutting lead time by weeks.

Contracts with suppliers should include clauses for expedited production or penalties for delays, incentivizing timely delivery. Flexible terms can also allow for adjustments in order quantities or delivery schedules.

Actionable Tip: Include escalation clauses in contracts to prioritize urgent orders during supply chain disruptions.

Example: An OEM could negotiate a contract with a casting supplier that allows for expedited delivery of engine blocks during peak production periods.

Regularly review lead time performance with suppliers to identify areas for improvement. Post-project debriefs can uncover inefficiencies and inform future strategies.

Actionable Tip: Conduct quarterly supplier reviews to assess performance metrics like on-time delivery and quality compliance.

Example: After a delayed delivery of fuel injectors, a manufacturer could work with the supplier to streamline their testing process, reducing future lead times.

While expediting production or diversifying suppliers can reduce lead times, these strategies often come with higher costs. Companies must balance the trade-offs between speed, cost, and quality. For instance, air freight can accelerate delivery but significantly increases expenses compared to sea transport. Similarly, maintaining large inventory buffers ties up capital. A data-driven approach, using tools like cost-benefit analysis or total cost of ownership (TCO) models, can help make informed decisions.

Managing long lead times for high-spec engine and powertrain components requires a combination of strategic planning, supplier collaboration, and technological innovation. By engaging suppliers early, diversifying the supply chain, leveraging technology, and maintaining robust forecasting, companies can mitigate delays and keep projects on track. While challenges like material shortages or global disruptions may persist, proactive management ensures resilience and competitiveness in demanding industries.

By implementing these strategies, businesses can turn the challenge of long lead times into an opportunity to optimize their supply chain and deliver high-quality products on time.

© 2025 Lasso Supply Chain Software LLC

Get instant access to our report on the Top Procurement Trends of 2025.

Get instant access to our report on the Top Procurement Trends of 2025 by filling out the form below.